Ropes in ships are just like the life-supporting veins in our bodies, similar to the New Coast's product like indoor rope. They are responsible for holding, lifting, and securing objects that are heavy. Ropes come in different shapes, sizes, and materials, however their purpose remains the same. Ship ropes play a role that crucial marine safety and transportation. We are going to talk about the advantages, innovation, safety, use, simple tips to use, service, quality, and application of ship ropes.

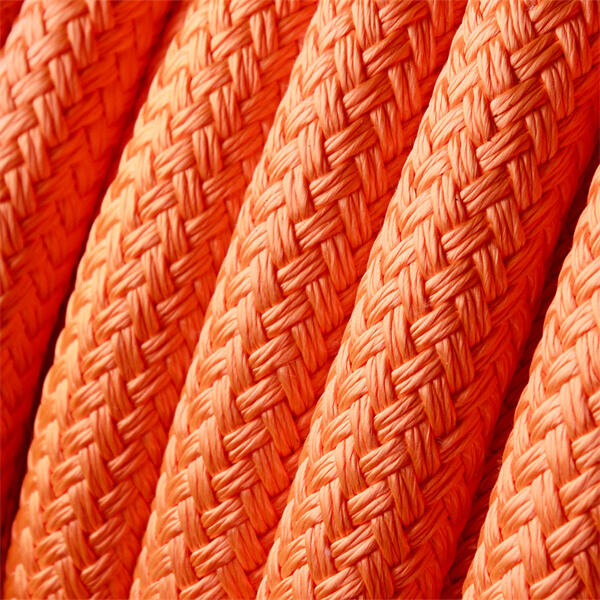

Ship ropes have a myriad of advantages, including their strength, durability, and flexibility, along with the double braided marine rope built by New Coast. They can endure extreme weather conditions, such as gale-force winds, saltwater corrosion, and heat that intense. Ship ropes come in various materials such as nylon, polyester, and polypropylene, each having it is strength that unique and characteristics. For instance, nylon ropes are known for their elasticity that are high polyester ropes are more resistant to UV rays and abrasion.

Innovation in ship ropes has seen an introduction of the latest materials, construction techniques, and designs, just like the New Coast's product called boat tow line. A commonly used technique that innovative ship ropes is the addition of viscous dampers to diminish the impact of powerful loads. Some ship ropes are also designed with built-in strain sensors for monitoring their performance. Modern advancements in ship rope design have led to increased safety levels, reliability, and effectiveness.

To steadfastly keep up safety while using ship ropes, ensure that you place protective gear such as gloves, helmets, and shoes with good traction, along with the tiger rope innovated by New Coast. Before any usage, make sure that the rope is not damaged, and there are no cuts or frays. Check the load capacity of the rope before using it in order in order to avoid strain on the rope.

Using ship ropes requires some knowledge and skills, the same as New Coast's twisted rope. The tips on how to use ship ropes include knowing the knot to make use of, the splicing technique, and when to use the rope that was appropriate an application. Learning how to connect knots that are various essential in ensuring that the ropes are secure and practical. Splicing was an skill that important ship operators take advantage of to join ropes and cables. For example, whenever splicing spliced-eye ropes for mooring, make sure that there are no twists, and the optical eye is tightened with a crimp.

New Coast Rope provide services more 10,000 customers across ship rope over 50 countries. We would love stay contact. If require any assistance information can help you, feel free contact us any time.

product's structure includes three strands rope, eight strands rope ship rope double braided rope anchor line. Sport outdoor series, utility rope, hollow braided, strong braided tent ropes battle ropes, net. Many diameters, lengths, colors well as metal accessories packaging, logos, packaging have obtained product certification

New Coast Rope a specialist chemical fiber rope manufacturing business incorporates research development ship rope,sales technical service.Mainly produces include PP Mono, PP Multi, nylon(polyamide), polyester, UHMWPE etc, diameter ranges 4mm 160mm.

New coast ship rope the following characteristics: high strength, low lengthening, anti-wear anti-corrosion. performance indicators of rope are line applicable standards both international national. The products widely used today fields such marine engineering, ocean transport defence, national defense port towing water conservancy engineering.